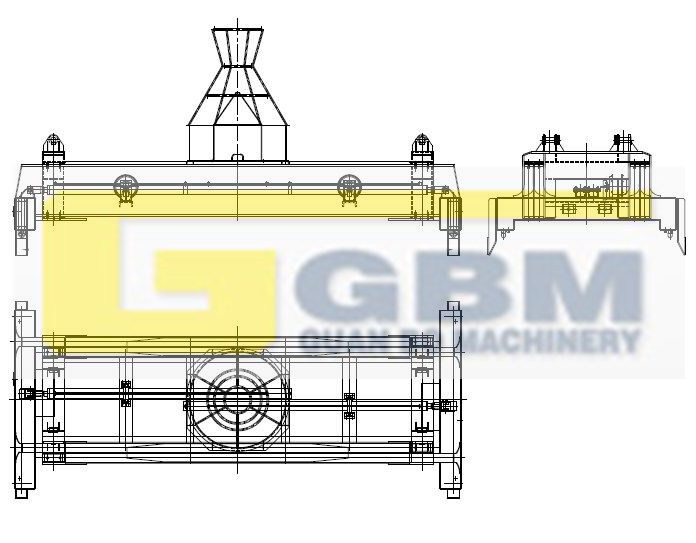

Electric spreader

The strict quality control system and the research and development concept of the electric spreader have led to the high quality of the GBM spreader, making the spreader production serialized, standardized in assembly, and versatile in parts. The pursuit of high quality, high reliability, to ensure that each product is exquisite boutique. The working conditions of spreaders are rather harsh. In order to meet the requirements of terminal use and reduce the failure rate of terminal spreaders, GBM strictly controls the materials used in the materials selection. High-strength steel plates are used to make all important components, which make them lightweight and high in strength. . In order to improve product quality, ZPMC has invested heavily in the development and purchase of new types of processing and inspection equipment. At the same time, it adopts advanced technological means, adheres to a complete inspection and testing system, and has passed a fatigue test bench, a heavy-duty functional test bench, and an impact test. Taiwan and other test stations of various types of 33 tests to ensure the rationality of the spreader structure and the durability of the parts.

| Suitable for operating ISO standard 20 feet 40feet container | Suitable for operating ISO standard 20feet 40feet container | AC 220V( Optional) | |

| Rated lifting capacity | 41T | total power | ≤8kw |

| Permissible load eccentricity | ±10% | Protection class | IP 55 |

| Tension lug weight | 10t*4 | System working pressure | 100 bar |

| Weight (spreader part) | 14.5T | Ambient temperature | -20℃~+45℃ |

| Retractable (20 feet to 40feet) | ~30s | Twist lock mode | ISO Floating Revolver, Cylinder Drive |

| Revolving (90°) | ~1s | Telescopic Drive | Hydraulic Motor Drive Sprocket/Roller Chain Drive |

| Guide Plate (180°) | 5~7s | Guide Plate Device | Detachable Guide Plate |

| Self-aligning (±1200mm | ~25s | Rotary Drive | Hydraulic Motor Drive |

| Rotation(±220°) | ~35s | Application | Ship unloader, Track Crane, Tire Crane, Portal Crane, Boom Crane |

© Copyright - 2018-2021 : All Rights Reserved.

© Copyright - 2018-2021 : All Rights Reserved.