Factory source Over Height Spreader - Electric spreader – GBM

Factory source Over Height Spreader - Electric spreader – GBM Detail:

Advantages for GBM Electric spreader

1.Electric container spreaders accommodate various sizes, easily accommodating 20ft ,30ft, 40ft containers. This flexibility saves time, also ensures optimum productivity by eliminating the need for manual adjustments.

2. The spreader’s advanced electrical system provides smooth, precise control for efficient lifting and lowering of containers. Spreader ensures a secure hold on the container, minimizing the risk of accidents or damage during lifting and transport.

3. It is equipped with advanced safety features, such as overload protection and anti-sway control, which guarantee the safety of operators and containers.

4. Designed to improve the efficiency and safety of container handling operations, also maintenance of the electric container spreader is very simple.

Why choose GBM as your spreader supplier?

The strict quality control system and the research and development concept of the electric spreader have led to the high quality of the GBM spreader, making the spreader production serialized, standardized in assembly, and versatile in parts. The pursuit of high quality, high reliability, to ensure that each product is exquisite boutique. The working conditions of spreaders are rather harsh. In order to meet the requirements of terminal use and reduce the failure rate of terminal spreaders, GBM strictly controls the materials used in the materials selection. High-strength steel plates are used to make all important components, which make them lightweight and high in strength. .

In order to improve product quality, we has invested heavily in the development and purchase of new types of processing and inspection equipment. At the same time, it adopts advanced technological means, adheres to a complete inspection and testing system, and has passed a fatigue test bench, a heavy-duty functional test bench, and an impact test. Taiwan and other test stations of various types of 33 tests to ensure the rationality of the spreader structure and the durability of the parts.

GBM spreader experience in career

5unit 30FT Electrical spreader

Project located in Vietnam

2 unit Electric telescopic spreader

Project located in German

3 unit 20FT Electric push rod spreader

Project located in South Korea

4 unit Electric rotation container spreader

Project located in Italy

4 unit electric fully telescopic spreader

Project located in Columbia

2 unit Railway weighing rotating spreader

Project located in China

Q&A

Q1. Can the spreader be customized?

Yes, every customer’s working condition is different, all of our products can be customized depend on customers’ requirements,such as SWL,put your logo on spreader. if need, we also can do BV certification.

We could design different spreader for you:

- Mechanical spreader(manual)

- Semi-automatic spreader(Frame type and I type)

- Hydraulic telescopic container spreader

- Electrical telescopic container spreader

- Twin lift telescopic container spreader

- Overheight frame(OHF)

- Rotation spreader

Q2. How is shippment of container spreader?

Normally shipping grabs in special containers or bulk cargo vessel,which requires careful planning and preparation. Always make sure the spreader is secured so it doesn’t slide around during transport.

GBM have it own experienced department for safe delivery,utilizing the services of a professional will ensure that the mechanical spreader is securely in place and the container is ready to ship.

Q3. Do you have installation team for container spreader test?

Yes, GBM has own installation teams in China,not limited to use, we also have over-sea after-sales service and emergency spare parts reserves.

Q4:What is information do you need for provide drawing?

- What is the spreader type do you need?I type or frame type?

- What is the SWL of spreader do you need?

- What is the crane type and connection of crane and spreader?

Q5:What is documents GBM could support

1) The general layout of the hopper(including the main dimensions and performance parameters) and the structure specification.

2) Layout drawing, assembly drawing and processing drawing of wearing parts of each mechanism of the hopper

3) Electrical equipment system diagram, layout diagram, wiring diagram, and control principle diagram.

4) Cable, conduit or trunking layout.

5) The schematic diagram of the hydraulic system and its description.

6) Product structure diagram of purchased parts, instruction manual and maintenance manual.

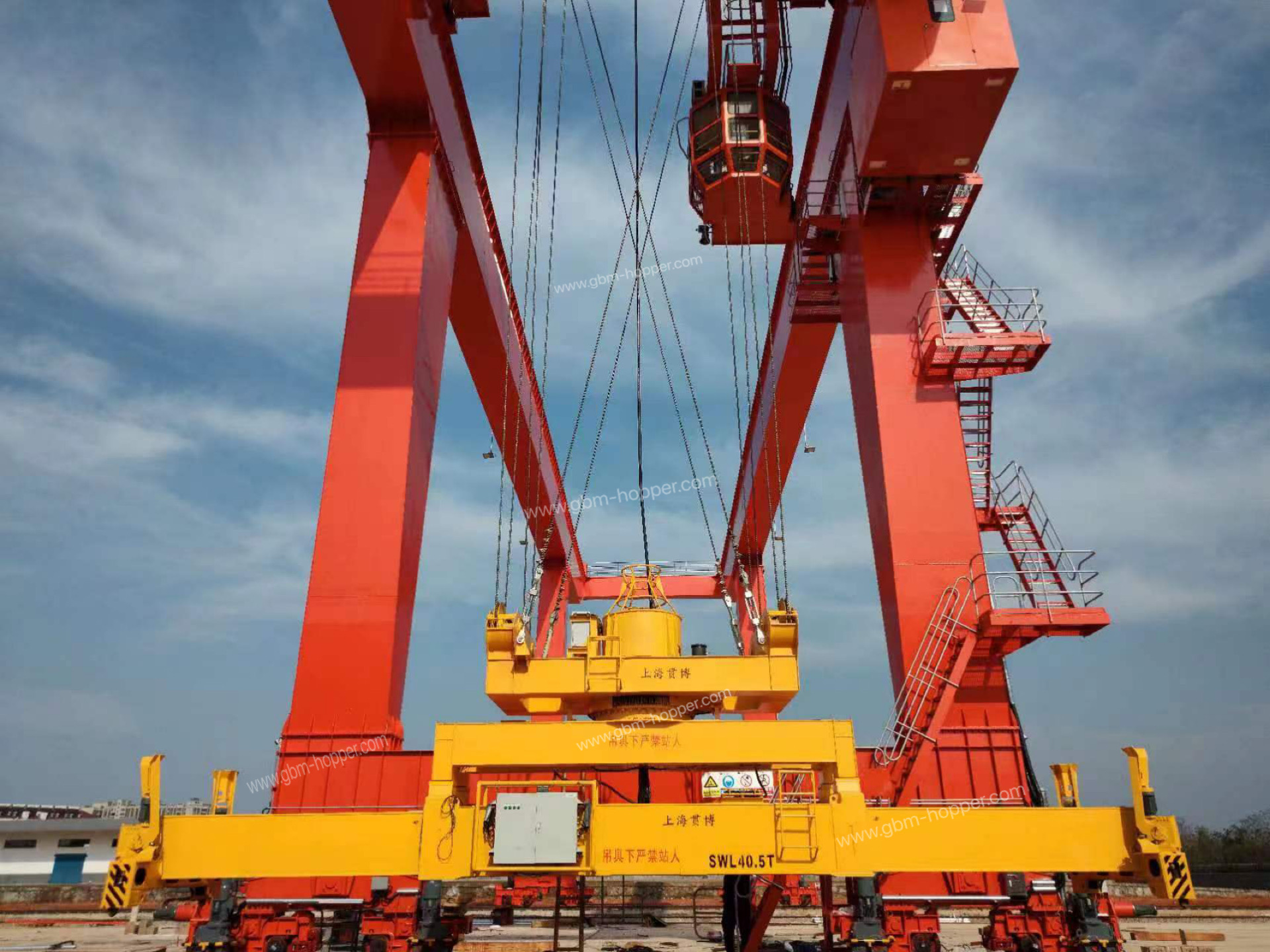

Product detail pictures:

Related Product Guide:

continue to improve, to ensure product quality in line with market and customer standard requirements. Our company has a quality assurance system have been established for Factory source Over Height Spreader - Electric spreader – GBM, The product will supply to all over the world, such as: Colombia, New Zealand, Indonesia, Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.

© Copyright - 2018-2021 : All Rights Reserved.

© Copyright - 2018-2021 : All Rights Reserved.