Nyekel gunting

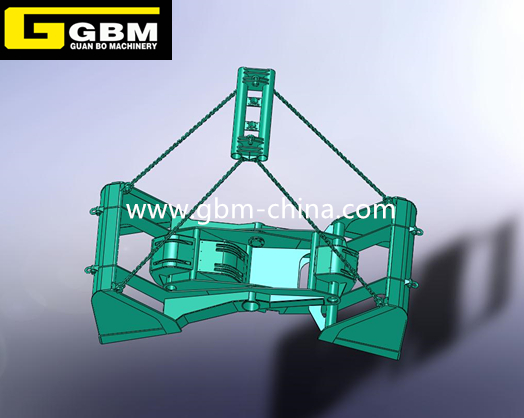

Scissor grab minangka alat penanganan massal sing efisien lan hemat energi sing dikembangake dening perusahaan kita.Grab nduweni kaluwihan ing ngisor iki:

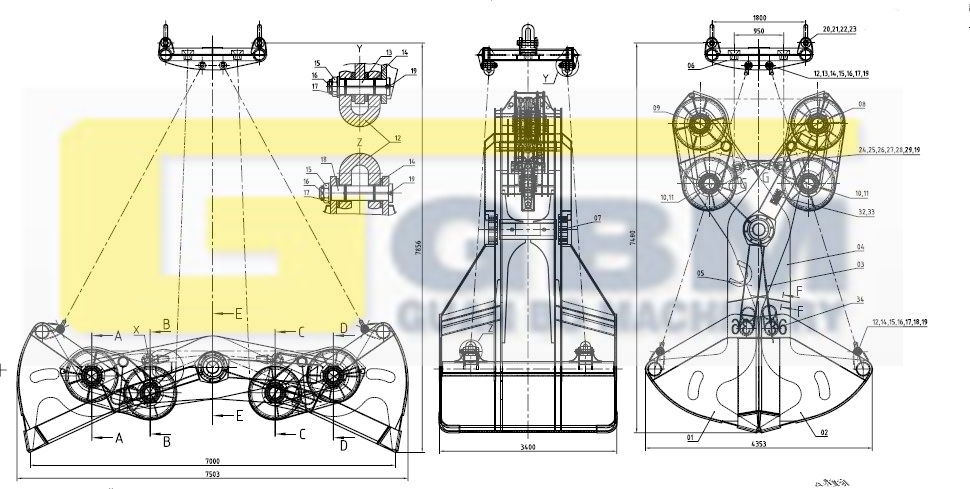

1. Grab saka dhuwur: 52 t bijih njupuk, contone, rutin dawa tetep bar njupuk bobot watara 20 t watara, njupuk rasio kira-kira 1,6, lan 52 t jinis potong njupuk poto-respect mung 17 t, njupuk rasio 2,05, saben. bab 3 t nyekel nyuda bobot;

2. High efficiency: ora mung nambah njupuk saka wis nemen nambah efficiency produksi, nglereni jinis njupuk ing grasping pasukan kebak mbukak kanggo nyekel barang ngeduk pasukan cilik, karo Tambah nyekel nutup pasukan ngeduk, kang konsisten karo pasukan ngeduk mung njupuk barang perlu, supaya entuk efficiency nemen apik, mung perlu bukaan cilik lan jadwal nutup bisa rampung ditutup, nyimpen kanggo nutup lan mbukak wektu, nambah efficiency;

3. Iku kondusif kanggo reresik: amarga bukaan gedhe saka ember shearing, area grasping saben ember punika 60% luwih dhuwur tinimbang kutub dawa, lan ora excavator lan mesin rake dibutuhake kanggo ngrampungake karya reresik.

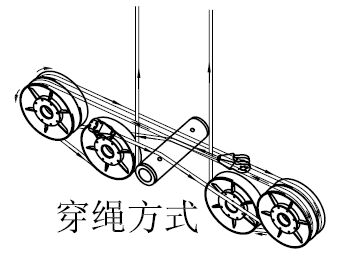

4. Tingkat kegagalan sing kurang: amarga jumlah gunting sing sithik lan poros kurang, iki nyuda tingkat kegagalan sawetara bagean sing rawan.Amarga iki kaluwihan saka nyukur nyekel, akeh gedhe akeh kargo nyekel ing bandar manca wis digunakake ing nyukur bucket.The nyekel ember bisa digunakake ing katrol beda crane noto, bisa digunakake ing sembarang mesin papat lawang kabel utawa unloading machine.Produk adopts teknologi desain virtual, lan USES ANSYS kanggo nindakake mriksa kekuatan lan Optimization kabeh bagean, supaya minangka kanggo nggawe njupuk poto-redistribute liyane cukup lan nggunakake urip maneh!

| Model | Kapadhetan materi (t/m3) | Bobot mati (Kg) | Total bobot ngangkat(t) | kapasitas (m3) | Katrol | Tali kawat | ukuran total (mm) | |||||||

| diameteripun | Magnification | diameteripun | dawa | stroke | A | B | C | D | E | |||||

| GBM10.0-1.6-4000 | 1.6 | 3600 | 10.0 | 4.0 | 450 | 2 | 22 | 14.0 | 4850 | 3740 | 4110 | 2510 | 4060 | 2460 |

| GBM12.5-1.6-5000 | 1.6 | 4500 | 12.5 | 5.0 | 500 | 2 | 24 | 15.0 | 5110 | 4090 | 4480 | 2620 | 4380 | 2580 |

| GBM16.0-1.6-6400 | 1.6 | 5760 | 16.0 | 6.4 | 560 | 2 | 26 | 16.5 | 5810 | 4480 | 4890 | 2760 | 4720 | 2760 |

| GBM20.0-1.6-8000 | 1.6 | 7200 | 20.0 | 8.0 | 630 | 2 | 28 | 18.5 | 6480 | 4960 | 5350 | 2960 | 5160 | 2940 |

| GBM25.0-1.6-10200 | 1.6 | 8680 | 25.0 | 10.2 | 630 | 2 | 32 | 19.6 | 6610 | 5100 | 5520 | 3260 | 5450 | 3170 |

| GBM32.0-1.6-12800 | 1.6 | 11520 | 32.0 | 12.8 | 710 | 2 | 36 | 21.0 | 7390 | 5690 | 6160 | 3520 | 6010 | 3320 |

| GBM40.0-1.6-16000 | 1.6 | 14400 | 40.0 | 16.0 | 800 | 2 | 40 | 23.8 | 8270 | 6320 | 3520 | 3820 | 6560 | 3520 |

| GBM50.0-1.6-20000 | 1.6 | 18000 | 50.0 | 20.0 | 900 | 2 | 44 | 25.5 | 8980 | 6760 | 7380 | 4120 | 6940 | 3790 |

| GBM63.0-1.6-25200 | 1.6 | 22680 | 63.0 | 25.2 | 1000 | 2 | 48 | 29.3 | 10780 | 7740 | 8280 | 4460 | 7910 | 4020 |

| GBM10.0-2.0-3300 | 2.0 | 3400 | 10.0 | 3.3 | 450 | 2 | 22 | 14.0 | 4850 | 3740 | 4110 | 2510 | 4060 | 2030 |

| GBM12.5-2.0-4100 | 2.0 | 4300 | 12.5 | 4.1 | 500 | 2 | 24 | 15.0 | 5110 | 4090 | 4480 | 2620 | 4380 | 2110 |

| GBM16.0-2.0-5200 | 2.0 | 5600 | 16.0 | 5.2 | 560 | 2 | 26 | 16.5 | 5810 | 4480 | 4890 | 2760 | 4720 | 2240 |

| GBM20.0-2.0-6600 | 2.0 | 6800 | 20.0 | 6.6 | 630 | 2 | 28 | 18.5 | 6480 | 4960 | 5350 | 2960 | 5160 | 2420 |

| GBM25.0-2.0-8300 | 2.0 | 8400 | 25.0 | 8.3 | 630 | 2 | 32 | 19.6 | 6610 | 5100 | 5520 | 3260 | 5450 | 2580 |

| GBM32.0-2.0-10400 | 2.0 | 11200 | 32.0 | 10.4 | 710 | 2 | 36 | 21.0 | 7390 | 5690 | 6160 | 3520 | 6010 | 2700 |

| GBM40.0-2.0-13000 | 2.0 | 14000 | 40.0 | 13.0 | 800 | 2 | 40 | 23.8 | 8270 | 6320 | 3520 | 3820 | 6560 | 2860 |

| GBM50.0-2.0-16200 | 2.0 | 17600 | 50.0 | 16.2 | 900 | 2 | 44 | 25.5 | 8980 | 6760 | 7380 | 4120 | 6940 | 3070 |

| GBM63.0-2.0-20400 | 2.0 | 22200 | 63.0 | 20.4 | 1000 | 2 | 48 | 29.3 | 10780 | 7740 | 8280 | 4460 | 7910 | 3250 |

© Hak Cipta - 2018-2021 : Kabeh Hak Dilindungi.

© Hak Cipta - 2018-2021 : Kabeh Hak Dilindungi.