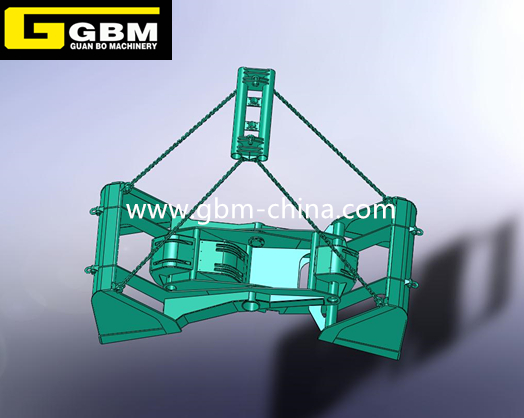

Scissor iaculis

Scissor iaculis est efficax et industria salutaris mole tractandi instrumentum a nostro comitatu elaboratum.Capto sequentia commoda habet:

1. Capto quam alto: 52 t ore capto, exempli gratia, exercitatione diuturna vectis capto pondus circiter 20 t circa, rationem fere 1.6, et 52 t genus capto sui respectu tantum 17 t incisum, rationem 2.05, sulum. de 3^t pondere capto minuere;

2. Maximum efficientiam: non solum emendare vagos quam multum augeri ad efficiendum efficientiam, incisionis speciei capto in apprehensione vis aperta ad capienda bona fodiendi vis parva est, cum incremento capto claudendi vim fodiendi, quae consentaneum est. vis fodiendi iusta mittentes bona indigent, ita efficaciam capto valde emendato, tantum opus est ut schedula minor aperiendi et claudendi clausa perficere possit, nisi ad tempus claudendi et aperiendi, efficaciam emendandi;

3. Conducit ad alvi: ob magnum foramen situlae tonsurae, area cuiusvis situlae comprehensio 60% altior est quam poli longi, et nulla machina excavator et sarculum opus alvi ad perficiendum requiritur.

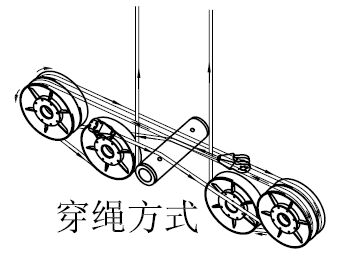

4. Minimum defectum rate: propter paucitatem forfices et minus axem, hoc minuit defectum partium vulnerabilium.Ob has commoda capto tondendi, multae molis onerariae magnae in portubus peregrinis in situla tondendas adhibitae sunt. Situla iaculis adhiberi potest in diversis machinae dispositionis ciconia, in quavis quattuor cable ostio machinae vel machinae adhiberi possunt. machina exonerare. Productum technologiam virtualem consilium capit, et usus ANSYS ad vim retardationis et optimiizationis omnium partium exsequendam, ita ut rationabilius rationabiliorem sui partem capto et vita longiore utatur!

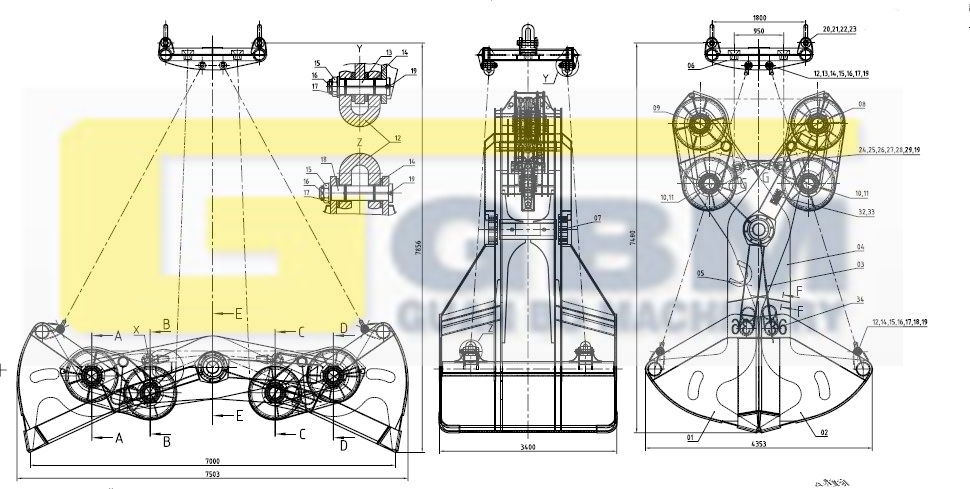

| Model | Materia densitas (t/ m3) | Mortuus pondus (Kg) | Totalis pondus elevatio(t) | facultatem (m3) | Pulley | Funis filum | altiore ratione (mm) | |||||||

| diametri | Magnificatio | diametri | longitudo | plaga | A | B | C | D | E | |||||

| GBM10.0-1.6-4000 | 1.6 | 3600 | 10.0 | 4.0 | 450 | 2 | 22 | 14.0 | 4850 | 3740 | 4110 | 2510 | 4060 | 2460 |

| GBM12.5-1.6-5000 | 1.6 | 4500 | 12.5 | 5.0 | 500 | 2 | 24 | 15.0 | 5110 | 4090 | 4480 | 2620 | 4380 | 2580 |

| GBM16.0-1.6-6400 | 1.6 | 5760 | 16.0 | 6.4 | 560 | 2 | 26 | 16.5 | 5810 | 4480 | 4890 | 2760 | 4720 | 2760 |

| GBM20.0-1.6-8000 | 1.6 | 7200 | 20.0 | 8.0 | 630 | 2 | 28 | 18.5 | 6480 | 4960 | 5350 | 2960 | 5160 | 2940 |

| GBM25.0-1.6-10200 | 1.6 | 8680 | 25.0 | 10.2 | 630 | 2 | 32 | 19.6 | 6610 | 5100 | 5520 | 3260 | 5450 | 3170 |

| GBM32.0-1.6-12800 | 1.6 | 11520 | 32.0 | 12.8 | 710 | 2 | 36 | 21.0 | 7390 | 5690 | 6160 | 3520 | 6010 | 3320 |

| GBM40.0-1.6-16000 | 1.6 | 14400 | 40.0 | 16.0 | 800 | 2 | 40 | 23.8 | 8270 | 6320 | 3520 | 3820 | 6560 | 3520 |

| GBM50.0-1.6-2000 | 1.6 | 18000 | 50.0 | 20.0 | 900 | 2 | 44 | 25.5 | 8980 | 6760 | 7380 | 4120 | 6940 | 3790 |

| GBM63.0-1.6-25200 | 1.6 | 22680 | 63.0 | 25.2 | 1000 | 2 | 48 | 29.3 | 10780 | 7740 | 8280 | 4460 | 7910 | 4020 |

| GBM10.0-2.0-3300 | 2.0 | 3400 | 10.0 | 3.3 | 450 | 2 | 22 | 14.0 | 4850 | 3740 | 4110 | 2510 | 4060 | 2030 |

| GBM12.5-2.0-4100 | 2.0 | 4300 | 12.5 | 4.1 | 500 | 2 | 24 | 15.0 | 5110 | 4090 | 4480 | 2620 | 4380 | 2110 |

| GBM16.0-2.0-5200 | 2.0 | 5600 | 16.0 | 5.2 | 560 | 2 | 26 | 16.5 | 5810 | 4480 | 4890 | 2760 | 4720 | 2240 |

| GBM20.0-2.0-6600 | 2.0 | 6800 | 20.0 | 6.6 | 630 | 2 | 28 | 18.5 | 6480 | 4960 | 5350 | 2960 | 5160 | 2420 |

| GBM25.0-2.0-8300 | 2.0 | 8400 | 25.0 | 8.3 | 630 | 2 | 32 | 19.6 | 6610 | 5100 | 5520 | 3260 | 5450 | 2580 |

| GBM32.0-2.0-10400 | 2.0 | 11200 | 32.0 | 10.4 | 710 | 2 | 36 | 21.0 | 7390 | 5690 | 6160 | 3520 | 6010 | 2700 |

| GBM40.00-2.0-13000 | 2.0 | 14000 | 40.0 | 13.0 | 800 | 2 | 40 | 23.8 | 8270 | 6320 | 3520 | 3820 | 6560 | 2860 |

| GBM50.0-2.0-16200 | 2.0 | 17600 | 50.0 | 16.2 | 900 | 2 | 44 | 25.5 | 8980 | 6760 | 7380 | 4120 | 6940 | 3070 |

| GBM63.0-2.0-20400 | 2.0 | 22200 | 63.0 | 20.4 | 1000 | 2 | 48 | 29.3 | 10780 | 7740 | 8280 | 4460 | 7910 | 3250 |

© Copyright - 2018-2021 : All Rights Reserved.

© Copyright - 2018-2021 : All Rights Reserved.