Skavatur li jappoġġja l-grab idrawliku tal-injam

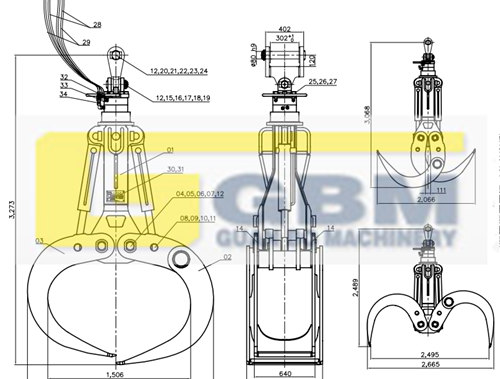

Il-grabs idrawliċi tal-injam huma magħmulin prinċipalment minn apparati mdendlin, ġonot rotanti, ċrieki li jduru, bolsters, ċilindri idrawliċi, u valvi tal-barmil.Il-korp tal-barmil u r-raġġ tal-bearing t'isfel huma konnessi b'xaft tal-pin;it-tarf tal-pistun taċ-ċilindru taż-żejt huwa ffissat fuq il-bolster, u l-virga tal-pistun hija mwaħħla fuq il-parti ta 'fuq tal-valv tal-barmil. Peress li l-virga tal-pistun taċ-ċilindru tiġi rtirata u estiża, il-korp tal-barmil idur bil-pin tal-pin tal-bearing kif punt taċ-ċappetta, li jlesti l-ftuħ u l-għeluq tal-barmil tal-grab.Il-grabs tal-injam idrawliċi jintużaw ma 'skavaturi u mhumiex imħaddma minnhom infushom, billi jiddependu fuq iż-żejt idrawliku bi pressjoni għolja pprovdut mill-iskavatur bħala sors ta' enerġija.L-iskavatur jiġbed żejt idrawliku bi pressjoni għolja fis-sistema tal-ftuħ u l-għeluq tal-grab, u jikkontrolla l-ftuħ u l-għeluq tal-grab billi jikkontrolla l-estensjoni u l-irtirar taċ-ċilindru.

| Mudell(GBM) | Piż mejjet (Kg) | SWL (t) | kapaċità (m3) | densità | Pressjoni massima tax-xogħol (bar) | Numru tal-barmil | Dimensjonijiet(mm) | |||||

|

| Agħlaq sħiħ | semi qrib | miftuħ sħiħ |

|

|

|

|

| A | B | C | D |

| GBM0.6-250 | 480 | 460 | 440 | 1.0 | 0.25 | 0.6 | 350 | 5 | 1570 | 1280 | 1140 | 1720 |

| GBM0.6-330 | 520 | 490 | 460 | 1.0 | 0..33 | 0.6 | 350 | 5 | 1670 | 1300 | 1240 | 2020 |

| GBM1.0-330 | 860 | 790 | 750 | 1.5 | .0.33 | 1.0 | 350 | 5 | 1740 | 1450 | 1260 | 1870 |

| GBM1.0-400 | 920 | 830 | 780 | 1.5 | 0.40 | 1.0 | 350 | 5 | 1790 | 1480 | 1320 | 1930 |

| GBM1.0-500 | 960 | 860 | 800 | 1.5 | 0.50 | 1.0 | 350 | 5 | 1880 | 1500 | 1400 | 2120 |

| GBM3.0-630 | 1030 | 930 | 880 | 2.0 | 0.63 | 1.0 | 350 | 5 | 1990 | 1520 | 1490 | 2280 |

| GBM1.0-800 | 1120 | 970 | 930 | 2.0 | 0.80 | 1.0 | 350 | 5 | 2090 | 1560 | 1600 | 2480 |

| GBM2.0-330 | 1180 | 1070 | 1050 | 2.0 | 0.33 | 2.0 | 350 | 5 | 1760 | 1410 | 1290 | 1980 |

| GBM2.0-440 | 1220 | 1100 | 1070 | 2.5 | 0.40 | 2.0 | 350 | 5 | 1800 | 1430 | 1350 | 2080 |

| GBM2.0-500 | 1280 | 1160 | 1120 | 2.5 | 0.50 | 2.0 | 350 | 5 | 1860 | 1460 | 1440 | 2200 |

| GBM2.0-630 | 1320 | 1200 | 1140 | 3.0 | 0.63 | 2.0 | 350 | 5 | 1920 | 1490 | 1520 | 2280 |

| GBM2.0-800 | 1780 | 1620 | 1540 | 4.0 | 0.80 | 2.0 | 350 | 5 | 2080 | 1680 | 1690 | 2430 |

| GBM2.0-1000 | 2020 | 1810 | 1670 | 4.0 | 1.0 | 2.0 | 350 | 5 | 2260 | 1730 | 1890 | 2750 |

| GBM3.0-1250 | 3430 | 3330 | 3180 | 10.0 | 1.25 | 3.0 | 350 | 6 | 3080 | 2670 | 1950 | 3130 |

| GBM3.0-1600 | 3710 | 3350 | 3340 | 10.0 | 1.60 | 3.0 | 350 | 6 | 3210 | 2710 | 2150 | 3400 |

| GBM3.0-2000 | 3760 | 3620 | 3450 | 10.0 | 2.0 | 3.0 | 350 | 6 | 3320 | 3010 | 2290 | 3630 |

© Copyright - 2018-2021 : Id-Drittijiet kollha Riżervati.

© Copyright - 2018-2021 : Id-Drittijiet kollha Riżervati.