Bamba isikere

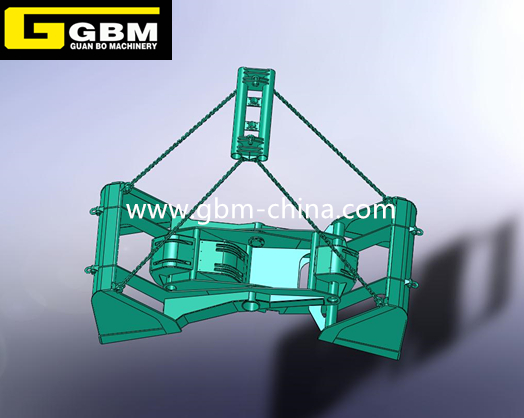

I-scissor grab sisixhobo sokuphatha isambuku esisebenzayo kwaye songa amandla esiphuhliswe yinkampani yethu.Ukubamba kunezi ncedo zilandelayo:

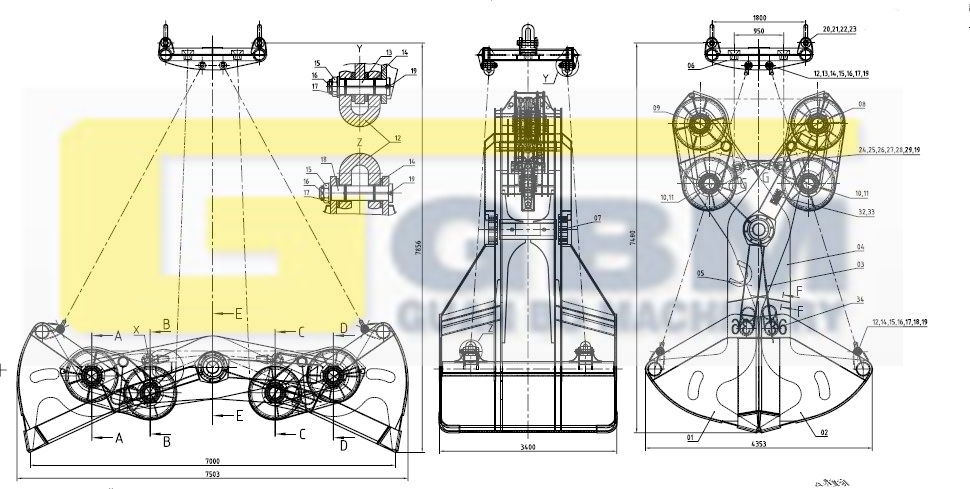

1. Bamba kunophezulu: 52 t ore bamba, umzekelo, yesiqhelo yokuhlala ixesha elide bar bamba ubunzima malunga 20 t ngeenxa, bamba umlinganiselo malunga 1.6, kunye 52 t cut uhlobo bamba ukuzihlonipha kuphela 17 t, ukulanda ratio 2.05, nganye malunga ne-3 t bamba ukunciphisa ubunzima;

2. Ukusebenza okuphezulu: kungekuphela nje ukuphucula ukulandwa kunokwandisa kakhulu ukusebenza kwemveliso, ukusika uhlobo lokubamba kumandla okubamba kuvuleleke ngokupheleleyo ukubamba iimpahla zokumba amandla amancinci, kunye nokwanda ukubamba ukuvala amandla okumba, ahambelanayo. amandla okumba athatha nje iimpahla eziyimfuneko, ngoko ke ukubamba ukusebenza kakuhle kuphuculwe kakhulu, kufuna kuphela ishedyuli encinci yokuvula kunye nokuvala kunokugqiba ukuvala, ukonga ixesha lokuvala kunye nokuvula, ukuphucula ukusebenza kakuhle;

3. Kukulungele ukucocwa: ngenxa yokuvulwa okukhulu kwebhakethi yokucheba, indawo yokubamba kwibhakethi nganye iphezulu ngama-60% ngaphezu kwepali ende, kwaye akukho matshini we-excavator kunye ne-rake efunekayo ukugqiba umsebenzi wokucoca.

4. Izinga lokungaphumeleli eliphantsi: ngenxa yenani elincinci le-scissors kunye ne-axle encinci, oku kunciphisa izinga lokungaphumeleli kwezinye iindawo ezisengozini.Ngenxa yezi nzuzo zokuhlutha i-shear, ezininzi imithwalo enkulu yomthwalo kwizibuko zangaphandle isetyenziswe kwi-emele yokucheba. ukukhulula umatshini.Imveliso ithatha itekhnoloji yoyilo lwenyani, kwaye ISEBENZISA i-ANSYS ukwenza ujongo lwamandla kunye nokulungiswa kwawo onke amalungu, ukuze wenze ukuba ukuhlutha ukusabalalisa kwakhona kube nengqiqo kwaye usebenzise ubomi obude!

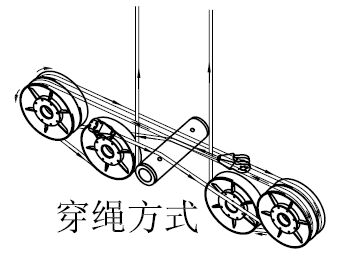

| Umzekelo | Ukuxinana kwezinto (t/ m3) | Ubunzima obufileyo (Kg) | Ubunzima bokuphakamisa bubonke(t) | umthamo(m3) | Pulley | Intambo yocingo | imilinganiselo epheleleyo(mm) | |||||||

| ububanzi | Ukwandiswa | ububanzi | ubude | istroke | A | B | C | D | E | |||||

| GBM10.0-1.6-4000 | 1.6 | 3600 | 10.0 | 4.0 | 450 | 2 | 22 | 14.0 | 4850 | 3740 | 4110 | 2510 | 4060 | 2460 |

| GBM12.5-1.6-5000 | 1.6 | 4500 | 12.5 | 5.0 | 500 | 2 | 24 | 15.0 | 5110 | 4090 | 4480 | 2620 | 4380 | 2580 |

| GBM16.0-1.6-6400 | 1.6 | 5760 | 16.0 | 6.4 | 560 | 2 | 26 | 16.5 | 5810 | 4480 | 4890 | 2760 | 4720 | 2760 |

| GBM20.0-1.6-8000 | 1.6 | 7200 | 20.0 | 8.0 | 630 | 2 | 28 | 18.5 | 6480 | 4960 | 5350 | 2960 | 5160 | 2940 |

| GBM25.0-1.6-10200 | 1.6 | 8680 | 25.0 | 10.2 | 630 | 2 | 32 | 19.6 | 6610 | 5100 | 5520 | 3260 | 5450 | 3170 |

| GBM32.0-1.6-12800 | 1.6 | 11520 | 32.0 | 12.8 | 710 | 2 | 36 | 21.0 | 7390 | 5690 | 6160 | 3520 | 6010 | 3320 |

| GBM40.0-1.6-16000 | 1.6 | 14400 | 40.0 | 16.0 | 800 | 2 | 40 | 23.8 | 8270 | 6320 | 3520 | 3820 | 6560 | 3520 |

| GBM50.0-1.6-20000 | 1.6 | 18000 | 50.0 | 20.0 | 900 | 2 | 44 | 25.5 | 8980 | 6760 | 7380 | 4120 | 6940 | 3790 |

| GBM63.0-1.6-25200 | 1.6 | 22680 | 63.0 | 25.2 | 1000 | 2 | 48 | 29.3 | 10780 | 7740 | 8280 | 4460 | 7910 | 4020 |

| GBM10.0-2.0-3300 | 2.0 | 3400 | 10.0 | 3.3 | 450 | 2 | 22 | 14.0 | 4850 | 3740 | 4110 | 2510 | 4060 | 2030 |

| GBM12.5-2.0-4100 | 2.0 | 4300 | 12.5 | 4.1 | 500 | 2 | 24 | 15.0 | 5110 | 4090 | 4480 | 2620 | 4380 | 2110 |

| GBM16.0-2.0-5200 | 2.0 | 5600 | 16.0 | 5.2 | 560 | 2 | 26 | 16.5 | 5810 | 4480 | 4890 | 2760 | 4720 | 2240 |

| GBM20.0-2.0-6600 | 2.0 | 6800 | 20.0 | 6.6 | 630 | 2 | 28 | 18.5 | 6480 | 4960 | 5350 | 2960 | 5160 | 2420 |

| GBM25.0-2.0-8300 | 2.0 | 8400 | 25.0 | 8.3 | 630 | 2 | 32 | 19.6 | 6610 | 5100 | 5520 | 3260 | 5450 | 2580 |

| GBM32.0-2.0-10400 | 2.0 | 11200 | 32.0 | 10.4 | 710 | 2 | 36 | 21.0 | 7390 | 5690 | 6160 | 3520 | 6010 | 2700 |

| GBM40.0-2.0-13000 | 2.0 | 14000 | 40.0 | 13.0 | 800 | 2 | 40 | 23.8 | 8270 | 6320 | 3520 | 3820 | 6560 | 2860 |

| GBM50.0-2.0-16200 | 2.0 | 17600 | 50.0 | 16.2 | 900 | 2 | 44 | 25.5 | 8980 | 6760 | 7380 | 4120 | 6940 | 3070 |

| GBM63.0-2.0-20400 | 2.0 | 22200 | 63.0 | 20.4 | 1000 | 2 | 48 | 29.3 | 10780 | 7740 | 8280 | 4460 | 7910 | 3250 |

© Copyright - 2018-2021 : Onke Amalungelo Agciniwe.

© Copyright - 2018-2021 : Onke Amalungelo Agciniwe.