I-Excavator hydraulic clamshell yokubamba

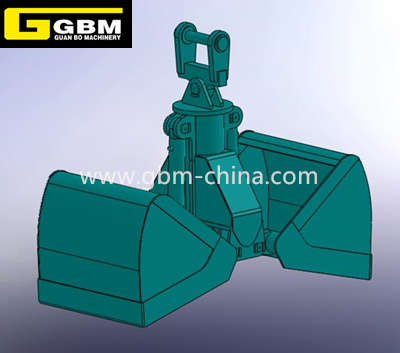

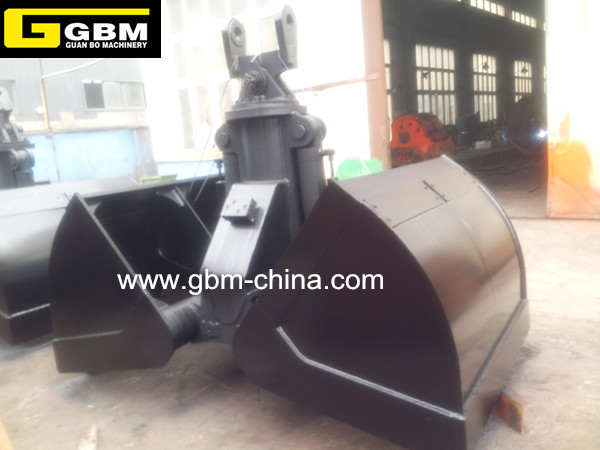

I-Excavator hydraulic clamshell grabis ikakhulukazi eyakhiwe idivayisi yokuphakamisa, i-bolster, isilinda sikawoyela, i-sub-fluid kanye nomzimba webhakede.Umzimba webhakede kanye ne-bolster kuxhunywe ngephini;ukuphela kwe-piston yesilinda samafutha kugxilwe ngaphezu kwe-bolster, futhi induku ye-piston igxilwe engxenyeni engenhla yomzimba webhakede.Njengoba induku ye-cylinder piston ihlehliswa futhi inwetshwa, umzimba webhakede uzungeza nephinikhodi ye-bearing pin njenge-hinge point, uqedela ukuvuleka nokuvala ibhakede lokubamba.Ipuleti lokuxhuma lilungisa kahle izindawo ezivulekile nezivaliwe zamabhakede amabili ukuze kuqinisekiswe ukuthi amabhakede angakwesokunxele nakwesokudla azungeza ngokuhambisanayo.Ibhakede le-hydraulic double-claw lisetshenziswa ne-excavator futhi alinikezwa amandla ngokwalo, lincike ku-hydraulic yokucindezela okuphezulu. uwoyela ohlinzekwa yi-excavator njengomthombo wamandla.I-excavator ihola yonke indlela uwoyela we-hydraulic high-pressure ohlelweni lokubamba lokuvula nokuvala, ukulawula ukuvulwa nokuvala ukubamba ngokulawula ukunwetshwa nokuhlehla kwe-cylinder ye-hydraulic;ukudweba enye i-high-pressure hydraulic oil ku-grab rotation system, nokulawula ukubamba ngokulawula ukujikeleza kwe-hydraulic motor.Ukuzungezisa ibhakede.

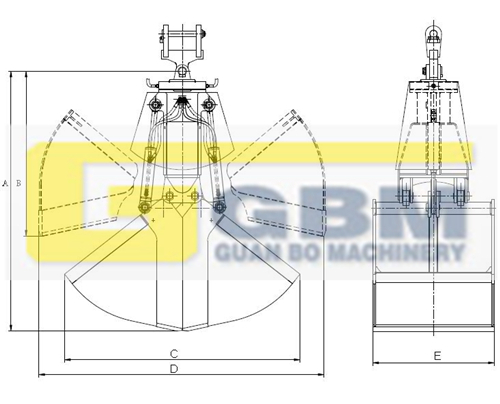

| Imodeli (GBM) | Amandla(m3) | Isisindo Esifile (Kg) | I-SWL (t) | Ingcindezi ephezulu yokusebenza (ibha) | I-engeli yokupakisha (°) | Ukuminyana (t/ m3) | Ubukhulu (mm) | ||||

| A | B | C | D | E | |||||||

| GBMG1.6-160 | 0.16 | 590 | 1.0 | 350 | 30 | 1.6 | 1850 | 1360 | 1420 | 1720 | 330 |

| GBM1.6-220 | 0.22 | 610 | 1.0 | 350 | 30 | 1.6 | 1850 | 1360 | 1420 | 1720 | 400 |

| GBM1.6-280 | 0.28 | 650 | 2.0 | 350 | 30 | 12.6 | 1850 | 1360 | 1420 | 1720 | 500 |

| GBM1.6-330 | 0.33 | 690 | 2.0 | 350 | 30 | 1.6 | 1850 | 1360 | 1420 | 1720 | 600 |

| GBM1..6-370 | 0.37 | 750 | 2.0 | 350 | 30 | 1.6 | 1850 | 1360 | 1420 | 1720 | 700 |

| GBM1.6-440 | 0.44 | 780 | 2.0 | 350 | 30 | 1.6 | 1850 | 1360 | 1420 | 1720 | 800 |

| GBM2.0-160 | 0.16 | 740 | 2.0 | 350 | 30 | 2.0 | 1980 | 1420 | 1340 | 1740 | 280 |

| GBM2.0-180 | 0.18 | 770 | 2.0 | 350 | 30 | 2.0 | 1980 | 1420 | 1340 | 1740 | 330 |

| GBM2.0-220 | 0.22 | 790 | 2.0 | 350 | 30 | 2.0 | 1980 | 1420 | 1340 | 1740 | 400 |

| GBM2.0-280 | 0.28 | 820 | 2.0 | 350 | 30 | 2.0 | 1980 | 1420 | 1340 | 1740 | 500 |

| GBM2.0-330 | 0.33 | 840 | 2.0 | 350 | 30 | 2.0 | 1980 | 1420 | 1340 | 1740 | 600 |

| GBM2.0-400 | 0.40 | 920 | 2.0 | 350 | 30 | 2.0 | 1980 | 1420 | 1340 | 1740 | 750 |

| GBM2.0-500 | 0.350 | 980 | 2.0 | 350 | 30 | 2.0 | 1980 | 1420 | 1340 | 1740 | 900 |

| GBM2.6-260 | 0.26 | 1280 | 3.0 | 350 | 30 | 2.6 | 2200 | 1520 | 1480 | 1990 | 400 |

| GBM2.6-400 | 0.40 | 1360 | 3.0 | 350 | 30 | 2.6 | 2200 | 1520 | 1480 | 1990 | 600 |

| GBM2.6-520 | 0.52 | 1450 | 4.0 | 350 | 30 | 2.6 | 2200 | 1520 | 1480 | 1990 | 800 |

| GBM2.6-630 | 0.63 | 1760 | 4.0 | 350 | 40 | 2.6 | 2200 | 1520 | 1480 | 1990 | 950 |

| GBM2.6-800 | 0.80 | 1860 | 4.0 | 350 | 40 | 2.6 | 2390 | 1580 | 1660 | 2160 | 1000 |

© Copyright - 2018-2021 : Wonke Amalungelo Agodliwe.

© Copyright - 2018-2021 : Wonke Amalungelo Agodliwe.